Harry Thaler

2D becomes 3D

A 2.5 mm thin aluminium sheet is transformed into a sustainable chair in a pressing process. The Pressed Chair gets the necessary stability from circumferential indentations and curvatures that also give it its characteristic outer appearance at the same time.

Material

Chair: Aluminium untreated or powder-coated (glossy)

Glider: Thermoplastic polyurethane (TPU)

Production

The Pressed Chair is manufactured by a high-tech automobile supplier in Bavaria.

Unfortunately the purchase price cannot be displayed in your country. Please send us a request

Pressed Chair

Design: Harry Thaler, 2011

High-tech Chair

In a company, which manufactures the hot curves of automotive chassis on a daily basis, our Pressed Chair finds itself in exactly the right hands. First, the contour is cut from a 2.5 mm thin piece of aluminium. In the second step the circulating curves and indentations are pressed into the material. Legs and backrest ultimately capture the correct angle using a mould. Incidentally, we initially tested the extreme carrying capacity of this construction using a number of sandbags. TÜV Rheinland later gave it their official seal.

The very beginning

Nils Holger Moormann discovered Harry Thaler as part of a talent platform at the Cologne furniture trade fair. The idea of producing a functional chair from a two dimensional piece of sheet metal, fascinated us from the outset. However, simple as it may look, the process was anything but. The development of the Pressed Chair ranks as one of the most lengthy and complex of all. But it was worth it. The Pressed Chair with its special construction and manufacture methods is ultimately a discovery in the world of furniture.

Chair

Aluminium untreated or powder-coated (glossy)

Glider

Thermoplastic polyurethane (TPU)

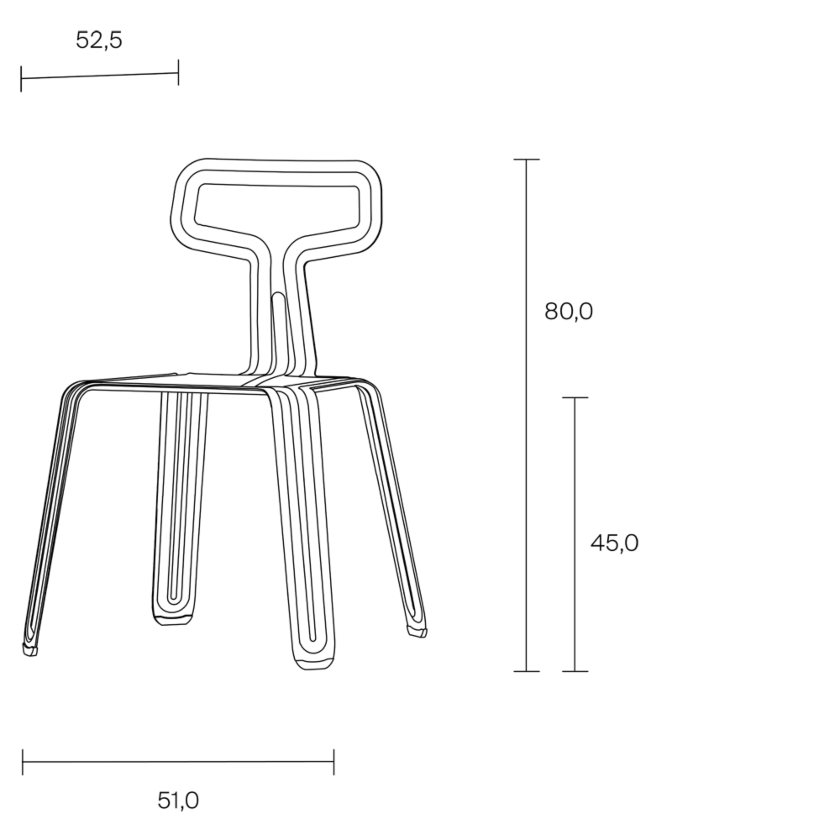

Dimensions in cm

Height: 80.0

Width: 51.0

Depth: 52.5

Seating height: approx. 45.0

General Information

Material thickness: 2.5 mm

Weight: 2.8 kg

Load capacity: max. 120 kg

Stackable, up to 6 chairs.

Suitable for outdoor areas.

To protect the floor plastic gliders have been attached to the feet.

At a minimum purchase of 12 units, any customised colours (RAL) are possible.

Version 'Aluminium untreated': Processing traces are visible. The material shows minor irregularities which can become more pronounced in the course of time. Visible rubbing e.g. on lighter coloured clothes is possible.

RAL / NCS Colours

Traffic White (RAL 9016)

Not White (RAL 1013)

Black 815 (RAL 9005)

True Red (RAL 3000)

Blue Collar (approx. RAL 5002)

Friesian Yellow (RAL 1018)

Dusky Pink (NCS S 1515-Y90R)

Certification

DIN 68878 and DIN EN 12520 approved, report number 211 87 595, 3.8.2012 by TÜV Rheinland/LGA. Thereby the stability, durability and safety for residential areas is verified.

Shipping and Assembly

The chair is delivered in its arched state and is ready for use.

Do you have any questions about our furniture?

We have answers.

Telefon +49 8052 9040-0

E-Mail info@moormann.de